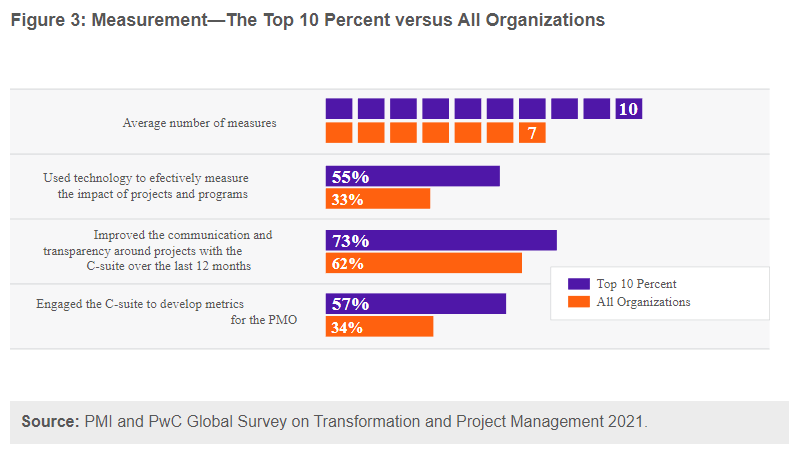

We believe numbers say more than words

The team members present expressive results in the sector

The best solutions for industries and factories

How do you feel knowing that you might be spending more on your projects than you should?

The Artrix-Octtan team of specialists has years of experience in defining industrial solutions, looking for the highest possible result with the lowest investment. This is possible due to the high knowledge in key areas of Development Engineering such as Processes, Automation, Mechanics, Electrical, Software, Simultaneous Engineering and Project Management.

We are an Industrial Process Design Engineering for companies that:

– Do not have a Development Engineering for their projects.

– Share the same Engineering to maintain existing industrial processes and for new projects.

– Already have a Development Engineering dedicated to new projects, but want to increase their technical knowledge in the new products launching or face a lack of resources due to the high load of projects.

Areas we operate

Artrix-Octtan operates in several Industrial Process segments, ensuring a complete development of your project, regardless of the technology that needs to be used.

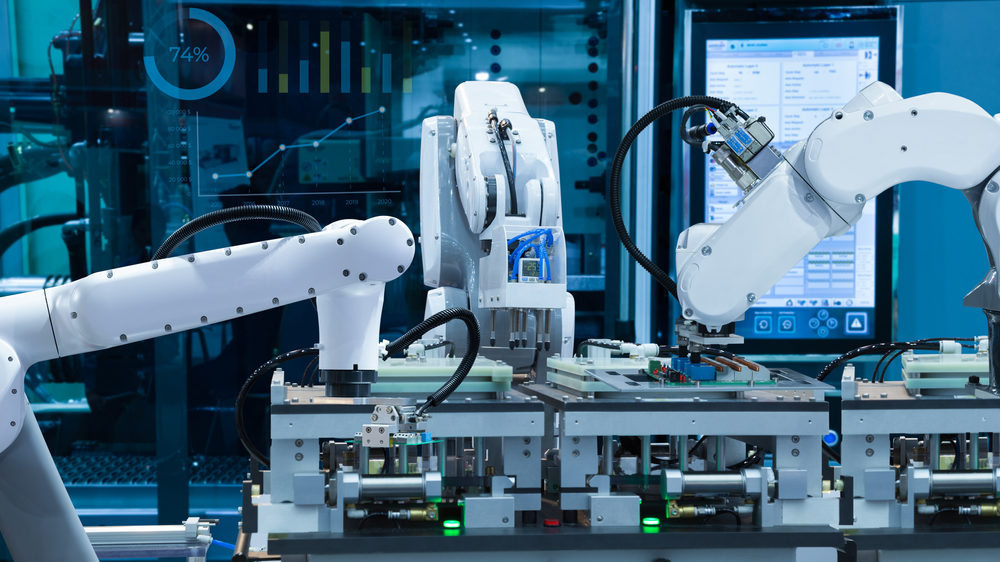

Robotics

Robotic projects require a lot of analysis and study to confirm the possibility of robotizing a process and ensuring the cycle times.

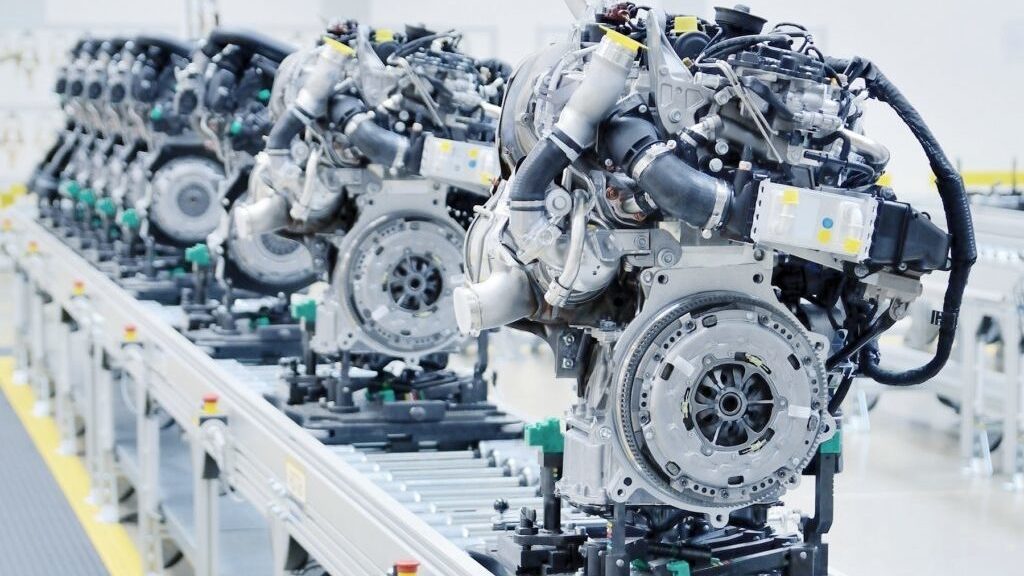

Assembly

Complex parts assembly projects require attention to Product and Process development with DFA and MTM.

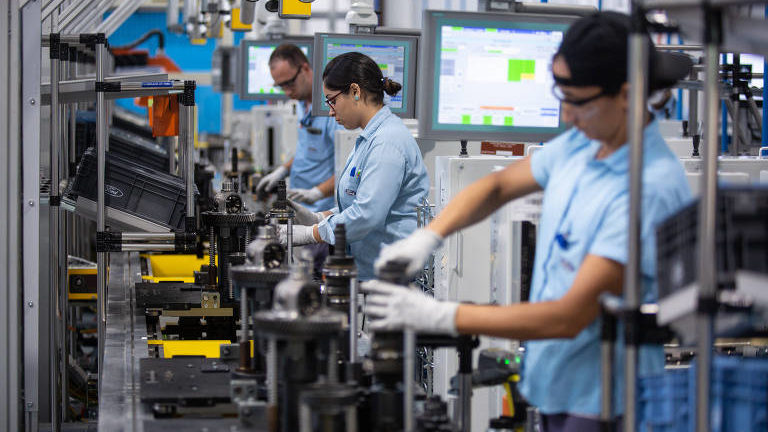

In-line and end-of-line (EOL) tests

A balanced definition of tests during the production process and at the end of the line ensures the delivery of quality parts to the customer.

Automatic and visual inspections

The correct definition of complex machine vision and operator inspection processes are essential to ensure process stability.

Product and Process Traceability

A correct concept during the process of defining the Product traceability data and all stages and results of the Process ensures robust data for studies of quality assurance and efficiency of the industrial process.

Material Flow

Efficient definition of material flow within the production line and factory are key factors for lean manufacturing.

Industries that we operate

Automotive

Aerospace

Naval

Consumer Goods

Tier 1, 2 e 3

General Manufacturing

Methodologies

Artrix-Octtan uses the world’s most advanced design methodologies, requested by large automotive and aerospace companies. The methodologies used in the development of our projects have undergone audits of automakers and central audits, meeting the high requirements of IATF 16949.

Process Flowchart

We develop a detailed process flow with all manufacturing steps. This makes it much easier to understand the product manufacturing process and make future modifications and improvements.

Control Plan

We create the Process Control Plan that organizes all the information about the current controls on the production line such as control method, sample, evaluation technique, tolerance, etc.

Design for Manufacturing and Assembly (DFMA)

We work together with Product Engineering to make the best adjustments in the design of the product. These adjustments will facilitate the manufacturing and assembly processes, so we can ensure better efficiency in industrial processes.

Design Failure Modes and Effect Analysis (DFMEA)

We work with the Product Engineering to analyze the effect and severity data of the failure modes in DFMEA for the preparation of PFMEA. Thereby we can ensure consistency in engineering documentation.

Process Failure Modes and Effect Analysis (PFMEA)

We analyze all the failure modes at all stages of the process. This allows us to define productive controls to prevent the sending of non-conforming parts to the end customer, ensuring a high-quality rate and a good reputation for the company name.

Fluxograma de Processos

Desenvolvemos um fluxo de processos detalhado com todas as etapas de manufatura. Com isso é muito mais fácil entender o processo de manufatura do produto e fazer futuras modificações e melhorias.

Special Product and Process Characteristics (SPPC)

We analyze the special characteristics defined by Product Engineering and create new special Process characteristics. This ensures that special controls are defined for the correct fulfillment of product and process requirements such as safety, regulation, primary functions, etc.

Machinery Failure Modes and Effect Analysis (MFMEA)

We support the suppliers of special machines in the analysis of all potential failures of the equipment and machines. Thereby the equipment can be developed robustly, avoiding the sending of non-conform products to the customer due to the failures in the machines used in the production process.

Lean Manufacturing

All projects are defined and specified based on lean manufacturing methodology. Therefore, factories can increasingly improve internal production processes, reaching increasingly high levels of internal organization, efficiency and quality.

Project Management

All projects are managed with a high level of project management, ensuring the correct planning, on-time delivery, scope control, cost monitoring and resource management, as well as knowledge retention and stakeholder management. Thereby we can ensure that several Engineering works simultaneously on the same project, even if the team is not in the same location or are from the same organization.

Companies

The team members have already led the complete development of industrial projects for the following companies.

Partners

Artrix-Octtan works in the design of Industrial Processes with some of the most technological companies in the market.

Countries

Artrix-Octtan members have already worked on large projects with customers, suppliers, vendors and partners from several regions of the world.

Projects

Artrix-Octtan members have already led the complete development of important projects of Production Process Design.

VW ID Crozz

Complete design and definition of highly complex production lines for the production of external handles.

INEOS Grenadier

Complete design and definition of highly complex production lines for the production of internal and external handles, kinematics, ignition and key.

Hyundai Creta

Complete design and definition of highly complex production lines for the production of the internal and external door handle.

What are they saying

Newsletter

Sign up to stay up to date with all the news about our company.

We are a Research and Development Engineering (R&D) in industrial processes. We create and define the most efficient and innovative processes on the market for any industry. Contact us, it will be a pleasure to provide more information.

Links

Contato

- Av. Paulista, 1636 São Paulo - Brazil

- www.artrix-octtan.com

- info@artrix-octtan.com

- (+55) 11 49633181