Areas of Expertise

Artrix-Octtan uses some of the most advanced Engineering Design techniques, tools and methodologies to manage development projects. Thereby we can ensure quality during all implementation phases of your projects in a wide range of areas of activity.

Simultaneous Engineering

Design for Manufacturing and Assembly (DFMA)

We work together with Product Engineering to make the best adjustments to the product design. These adjustments will facilitate the manufacturing and assembly processes, thus ensuring better efficiency in industrial processes.

Design for Data Analysis

We understand that the world has changed and data analysis is increasingly being used for the growth of organizations. In order to make assertive and efficient decisions at the factory, robust data is needed to guide the Industrial Engineering team. Therefore we act in the definition of industrial processes prepared for the acquisition of data that allow the traceability of the Product and Process. The Process Engineering and Quality team will have real data to understand and improve the developed processes.

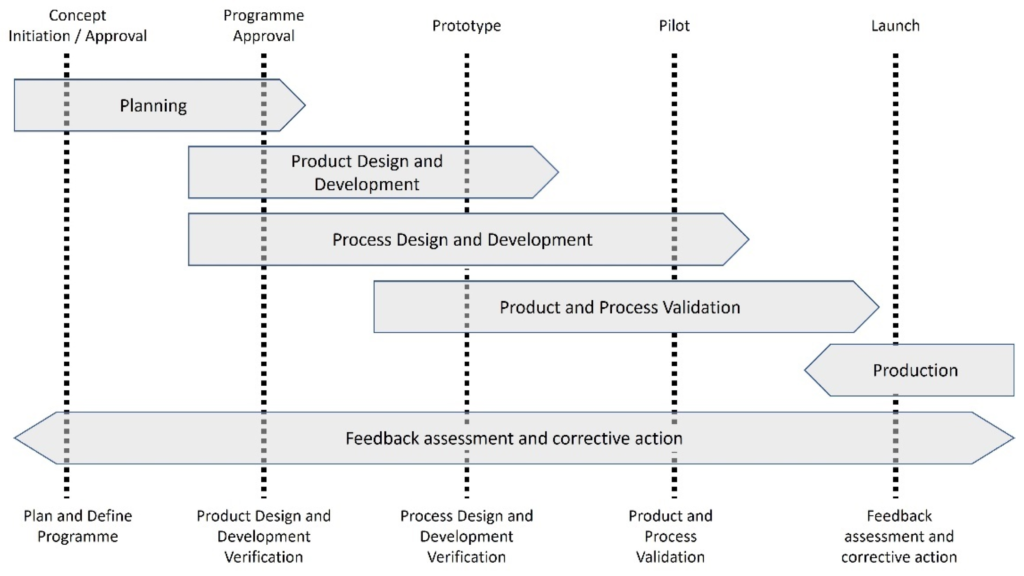

Advanced Product Quality Planning - APQP

The APQP is a methodology widely applied in the automotive and aerospace segments, but it is being strongly adhered to by other segments in the development of their products. This methodology approach development activities and phases to ensure the quality of product development. Artrix-Octtan is fully prepared to act in all phases of APQP with simultaneous engineering. This makes us even more assertive and efficient during development.

Design reviews and validations

During the development of complex projects, we work with several engineering areas simultaneously. So that we can guarantee that all requirements are met, we have constant project review and validation meetings with various areas such as Product Design, Process Design, Automation, Maintenance, Ergonomics, Safety and so on.

Quality incident analysis

We understand that organizations are increasingly concerned about recurring quality incidents, especially on new projects. To avoid these problems, we work together with your Process and Quality team to understand the analyzes made of the current quality problems that are related to the project under development. This allows us to be more assertive and avoid the recurrence of problems in new projects.

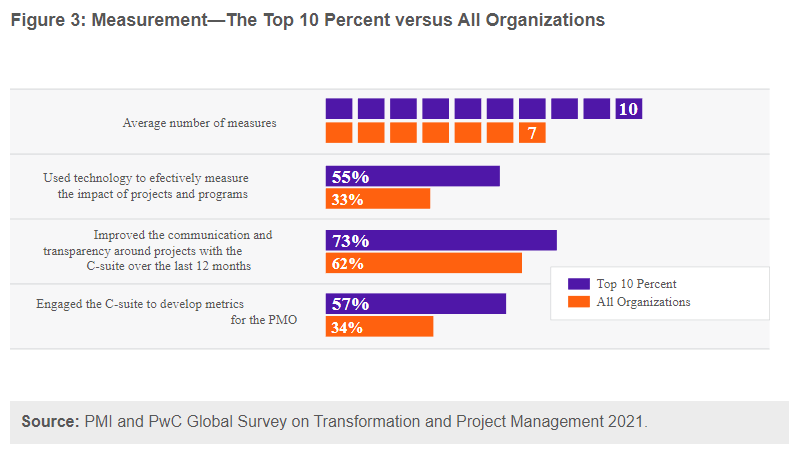

Project Management

Project risk assessment

A robust risk analysis is increasingly being applied in organizations. Artrix-Octtan assesses the risks involved in the projects so that preventive actions can be taken, such as elimination, mitigation, transfer or acceptance. With a risk response plan in hand, we can quickly act when any threat to the project arises.

Project Schedule

We understand that we operate in a segment where meeting deadlines is extremely important. Artrix-Octtan uses some of the most advanced tools for managing schedules and resources, enabling seamless integration with your project schedule

Development Procedures

Complex projects require clear and robust procedures for carrying out each activity in the different phases of development. Artrix-Octtan has a robust development methodology, with well-defined processes for each stage of the process design project. This will help your organization to launch projects more efficiently, by respecting methods and activities that guarantee the quality of development.

Project Phases

The division of projects into phases is widely used to manage projects in organizations around the world. Artrix-Octtan has clear internal phases in the development of its projects, enabling their correct validation and approval before proceeding with the development. Thus, we were able to be more assertive and efficient by detecting any flaws in the design before the project get advanced.

Validation Procedures

Complex projects require robust validations to ensure that all requirements have been met, because due to the dynamics of information during a project, some requirements may be lost. Artrix-Octtan has clear procedures for validating our design projects and validating the means of production that will be built at the suppliers of special machines. Thus, we were able to be more efficient, avoiding the rework of the means of production after they had already been built and implemented in the factory.

Lessons Learned Database (LLC)

We understand that organizations increasingly want to avoid recurring errors, in order to be more efficient. Artrix-Octtan has the vision to do it right the first time, but to make this possible, we have a database of hundreds of lessons learned and design rules. This makes us more assertive, as we learn from old projects and work so that mistakes are not repeated.

Project planning

It is not possible to manage large Process Design projects if there is not good planning at the beginning of the project, in addition, it is in the planning phase that we must invest the most time. Artrix-Octtan has clear planning steps at the beginning of the project, including stakeholders to meet the schedule, fulfill the scope, ensure the quality of development among others.

Process Engineering

Process Failure Modes and Effect Analysis (PFMEA)

The Process FMEA is a failure analysis widely requested in the Automotive and Aerospace industry, it is also being strongly adhered to by several other segments. Artrix-Octtan analyzes all potential failure modes at every step of the process. This allows us to define production controls to prevent the sending of non-conforming parts to the final customer, ensuring a high-quality rate and a good reputation for the company's name.

Process Balancing

We understand that organizations are increasingly demanding in relation to the reliability of the Supply Chain with the consistency of deliveries. Maintaining productivity becomes even more difficult when a production line has multiple manual and automatic processes working simultaneously. Artrix-Octtan uses advanced tools and techniques to ensure a correct balance between all processes. This enables us to create Industrial Processes with more reliable productivity for your organization.

Process Specifications Book

Requirements, specifications and standards are widely used during the development of complex projects in different organizations around the world, especially when the projects include external partners that provide some kind of service or product. Artrix-Octtan defines and develops a Specifications Book with all the requirements, rules and standards for the development of industrial projects. Thus, we can be more assertive and efficient in monitoring projects in service providers and special machines.

Special Product and Process Characteristics (SPPC)

Defining special characteristics is a very important practice during Product and Process Design. Artrix-Octtan analyzes the special characteristics defined by Product Engineering and defines new special characteristics for the Industrial Process. This ensures that special controls are defined to correctly meet product and process requirements such as safety, regulation, primary functions, etc.

Design Failure Modes and Effect Analysis (DFMEA)

The Design FMEA is widely applied during the development of the Product, at this point, it is important that the Product and Process Engineering are aligned. Artrix-Octtan works together with Product Engineering, analyzing data on the effect and severity of failure modes in the DFMEA to prepare the PFMEA. Thus, we can guarantee consistency in the Engineering documentation.

Lean Manufacturing

Achieving increasingly lean manufacturing is a constant search for organizations since it directly affects the operating margin of companies. It is not acceptable that while the Industrial Engineering team is working to make the factory leaner, the Development Engineering team is creating projects that do not respect this rule. Artrix-Octtan has as one of the main methodologies Lean Manufacturing for all projects. This makes it possible to keep factories lean and consequently increase operating margins.

Industrial Layout

To keep factories leaner and leaner, organizations are taking more and more attention to the layout of production processes, as it directly affects the flow of materials on the factory floor. Artrix-Octtan focuses on design steps to define the best layout for industrial projects. As a result, we are able to be more efficient and keep our factories leaner.

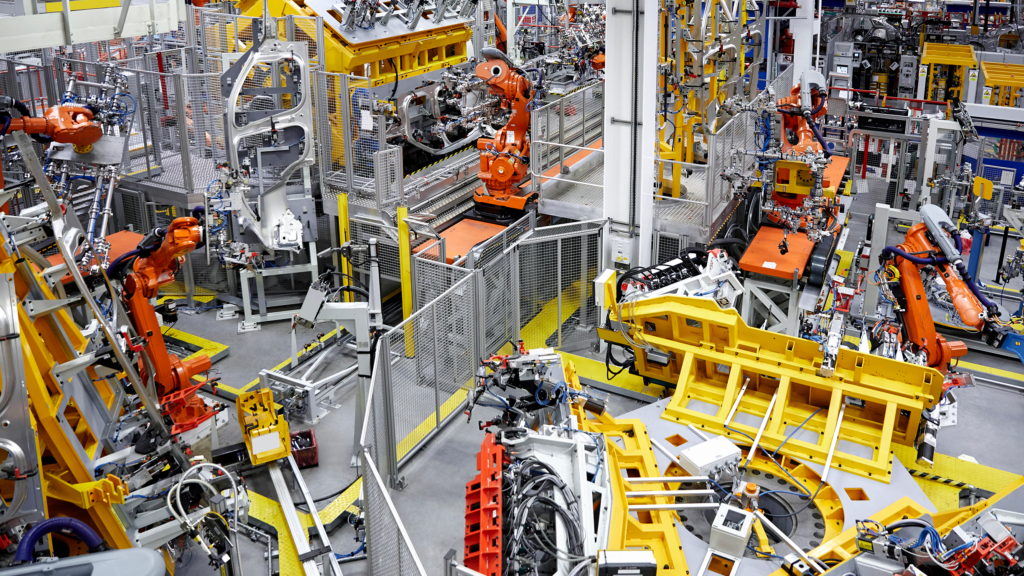

Automation Engineering

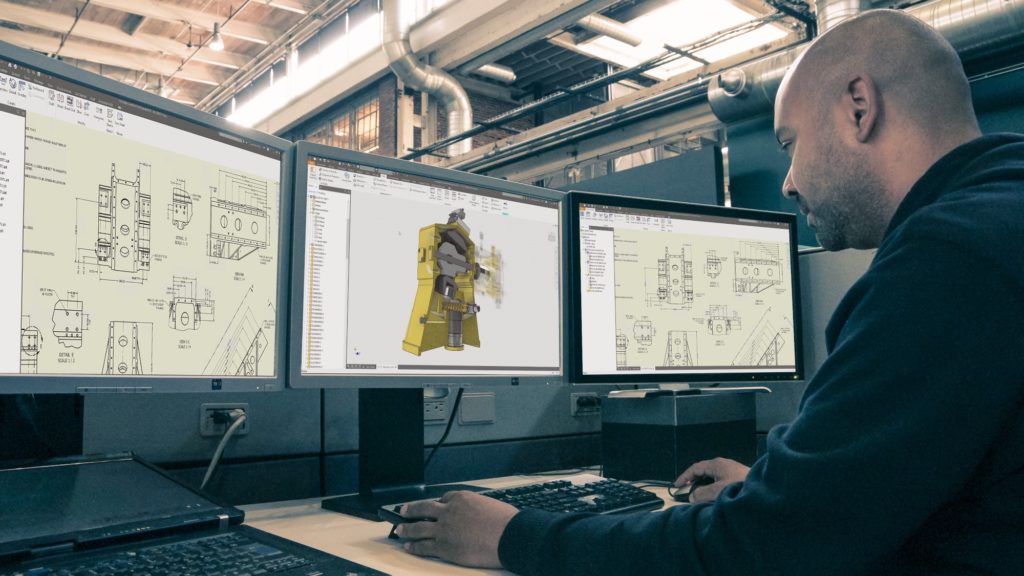

Mechanics

During the development of special machines and devices, attention to the mechanical concepts applied to the project is very important. The definition of a robust mechanical concept is crucial for the stability of the equipment and consequently of the production line. Artrix-Octtan has extensive experience with mechanical projects, so we can be more assertive during the project validation phase of suppliers of special machines.

Electrical and Electronics

Correct attention to electrical and electronics concepts during the development of special machines and devices must be taken into account in the design phase. Robust and well-defined concepts will ensure stable and reliable controls that will meet process capability requirements such as R&R, CPK, CMK etc. Artrix-Octtan has extensive experience and knowledge in electrical and electronic projects, so we can be more assertive during the project validation phase of special machines suppliers.

Software

For machines and equipment to work stably and reliably, a perfect integration between mechanics, electronics and software are crucial. A robust, well-organized and structured software design will guarantee the capability of the industrial process and the stability of the production line, as well as the agility and ease of possible future modifications. Artrix-Octtan has extensive experience and knowledge of the best software frameworks as well as validation procedures. Thus, we can be more assertive during the validation phase of the project and the production line of the special machines suppliers.

Industrial IT

The industrial world is increasingly connected, and acquisition and data analysis to make more assertive decisions are being widely used in organizations around the world. Artrix-Octtan has extensive experience in Industrial IT projects for Product, Process and Productivity data acquisition. This enables Quality and Process Engineers to make decisions with data during process analysis or when reporting an event to the customer. Thus, organizations can be even more efficient and assertive in decision-making at the factory.

Machinery Failure Modes and Effect Analysis (MFMEA)

The analysis of failure modes coming from machines is gaining a lot of strength in the market, detecting possible definition flaws during the design phase. Artrix-Octtan has extensive knowledge in Industrial Automation, which enables us to support suppliers of special machines in the analysis of all potential failure modes of equipment and machines. Thus, the equipment can be developed in a more robust way, avoiding the sending of non-conforming products to the customer resulting from failures in the machines used in the production process.

Newsletter

Sign up to stay up to date with all the news about our company.

We are a Research and Development Engineering (R&D) in industrial processes. We create and define the most efficient and innovative processes on the market for any industry. Contact us, it will be a pleasure to provide more information.

Links

Contato

- Av. Paulista, 1636 São Paulo - Brazil

- www.artrix-octtan.com

- info@artrix-octtan.com

- (+55) 11 49633181